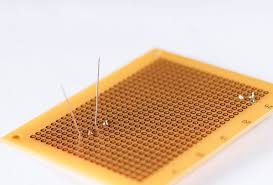

A PCB prototype is an initial sample or model of a printed circuit board (PCB) that engineers use to evaluate and test the design of the electronic circuit before full-scale manufacturing. The creation of a PCB prototype allows designers to detect potential issues and make necessary adjustments to improve functionality, efficiency, and durability.

Importance of PCB Prototyping

Early Detection of Design Flaws

Prototyping enables engineers to identify and rectify design errors early in the development process. This proactive approach reduces the risk of costly modifications later and ensures that the final product meets the desired specifications and performance standards.

Testing and Validation

Engineers use PCB prototypes to conduct tests that validate the circuit's performance under various conditions. This testing phase is crucial for assessing the reliability and stability of the PCB, ensuring it operates efficiently across different temperatures and voltage levels.

Integration and Compatibility

PCB prototypes allow designers to check how well a new circuit integrates with existing systems. This compatibility testing is essential for complex devices where multiple PCBs must work together seamlessly.

Key Considerations in PCB Prototyping

Material Selection

Choosing the right materials for a PCB prototype impacts its functionality and lifespan. Common materials include FR-4, a fiberglass-reinforced epoxy laminate, known for its strength and moisture resistance. The quality of the material directly affects the prototype's performance, particularly in harsh environments.

Dimensions and Specifications

The dimensions and specifications of a PCB prototype must align precisely with the intended final product. Typical dimensions include board thickness, which usually ranges from 1.0 mm to 2.4 mm, depending on the application. Specifications such as trace width and spacing are critical for ensuring that the PCB can handle the required electrical load without failure.

Cost and Budget Considerations

Creating a PCB prototype involves balancing performance with cost-efficiency. It's vital to consider the costs associated with different materials, manufacturing techniques, and testing procedures. A typical prototype may cost anywhere from $10 to $200, depending on complexity and the manufacturing process used.

Time and Speed

The speed of prototyping can significantly influence the time to market for new products. Rapid prototyping technologies enable engineers to iterate designs quickly, typically within days. This speed is essential in competitive industries where time to market can determine the commercial success of a new technology.

Advantages of PCB Prototyping

PCB prototyping offers several advantages:

- Reduces overall development costs by identifying problems early.

- Shortens development time by allowing simultaneous phases of design and testing.

- Increases the likelihood of product success by ensuring that the design meets all technical requirements.

In summary, PCB prototyping is a critical step in the design and production of electronic circuits. It ensures that the final PCBs are robust, efficient, and cost-effective, meeting both technical specifications and market demands.